In the rapidly changing perspective of the industrial world, material innovation plays a prominent role in considerations dealing with sustainability and performance. Polyurethane dispersion-PUD is an aqueous-based and environmentally friendly product that marked a revolution in the coatings and adhesives field. Since it is versatile, long-lasting, and has less environmental impact, PUDs have become one of the most reliable materials in many industries, from automotive to construction. In this article, let’s understand what polyurethane dispersion is and its benefits.

What is Polyurethane Dispersion?

Water-based polyurethane dispersion contains polyurethane polymers dispersed in water by forming a stable, milky emulsion. Unlike the traditionally used solvent-based coating of polyurethane, which relies on strong, harsh chemicals, PUDs take water as their prominent carrier. In such a way, it yields a product that would be much less harmful to the environment and much safer for workers and end-users.

The small polyurethane particles spread by a chemical process in water in the case of PUD. After Evaporating, the water leaves a strong polyurethane film on the surface with excellent adhesion, flexibility, and wear resistance. PUDs are helpful for many applications, such as paints, adhesives, and textiles.

The Science behind Polyurethane Dispersion

In the production of polyurethane dispersion (PUD), meticulous control is required during polymerization. The process involves breaking down polymer chains into small particles, which are then dispersed in water to form a fine mixture. This approach allows manufacturers to develop specific formulations that cater to various requirements, such as hardness, elasticity, or chemical resistance.

Unlike traditional solvent-based systems that release volatile organic compounds (VOCs), PUDs utilize water, resulting in minimal VOC emissions. This not only enhances the environmental friendliness of PUDs but also aligns with global regulations aimed at reducing the environmental impact of manufacturing processes.

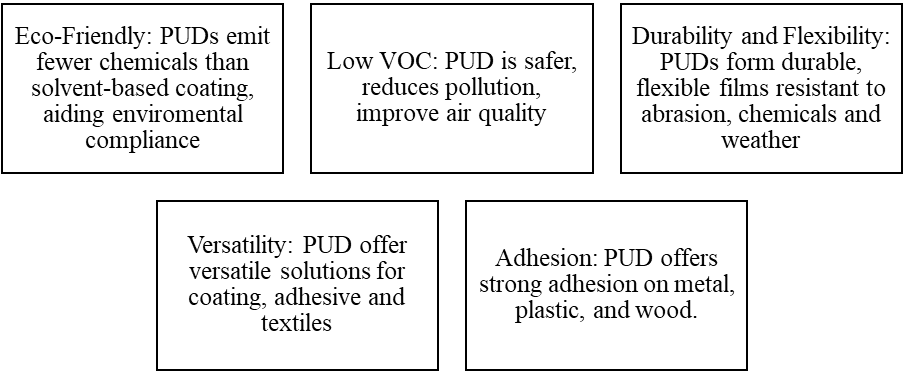

Key Benefits of Polyurethane Dispersion

Polyurethane dispersion has gained popularity due to its unique combination of properties that offer several advantages over traditional materials. Below are some of the most notable benefits:

Applications of Polyurethane Dispersion

The adaptability of polyurethane dispersion has made it a popular choice in many industries. Its performance, environmental benefits, and customization make it suitable for many applications. Some applications are:

1. Coatings

One of the most common uses of PUD is coatings, which offer durability, scratch resistance, and a smooth finish. Some examples include:

- Automotive Coatings: PUDs create high-gloss, durable finishes that protect vehicles from harsh environmental conditions.

- Wood Coatings: Furniture manufacturers use PUD-based coatings to provide resistance to scratches, moisture, and UV light while maintaining the wood’s natural look.

- Textile Coatings: PUDs can be applied to fabrics to make them water-resistant, durable, and flexible without compromising comfort or appearance.

2. Adhesives

PUD-based adhesives offer excellent bonding properties, flexibility, and resistance to heat and chemicals, making them ideal for:

- Footwear: In the shoe industry, PUD uses different materials like leather, rubber, and synthetic fabrics, ensuring durability and comfort.

- Laminating Adhesives: PUDs in laminating adhesives for applications such as film-to-foam bonding and flexible packaging, thanks to their strong adhesion and flexibility.

3. Textile Finishing

In the textile industry, PUDs are used as textile coatings for applications such as sportswear, upholstery, and outdoor fabrics. They add functionalities such as waterproofing, breathability, and resistance to wear and tear, making textiles more durable and comfortable.

4. Paper and Packaging

PUD is also used in the paper and packaging industries to create barrier coatings that protect against moisture and grease. This is particularly important in food packaging, where high-performance coatings are required to maintain product freshness and integrity.

Choosing the Right Polyurethane Dispersion

Given the versatility of PUDs, it’s essential to choose the right formulation for specific applications. Factors to consider include:

- Surface Type: the type of surface you are coating—such as wood, metal, or plastic—affects the adhesion properties required. For example, wood needs a PUD that can penetrate and bond well, while metal requires good adhesion to non-porous surfaces.

- Performance Requirements: Depending on whether you need hardness, flexibility, or chemical resistance, select a PUD that meets these mechanical properties. A hard finish may be required for high-wear areas, while flexibility is essential for surfaces that experience movement.

- Environmental Conditions: For outdoor use, choose a PUD with UV resistance to prevent issues like fading or degradation, and ensure it offers moisture resistance if exposed to high humidity or water.

Future of PUD

As industries increasingly shift toward more sustainable and eco-friendly materials, the demand for PUD is expected to grow. Innovations in the chemistry of PUDs are likely to result in even better performance characteristics, such as faster drying times, enhanced flexibility, and more significant resistance to extreme conditions.

Furthermore, as environmental regulations become more stringent worldwide, many companies are expected to replace solvent-based systems with PUDs in their manufacturing processes. This trend is already evident in industries such as automotive, textiles, and packaging, where the benefits of PUDs align with the growing focus on sustainability.

Conclusion

Polyurethane dispersion is a revolutionary material- a unique combination of performance, versatility, and environmental benefits. From coatings and adhesives to textiles and packaging, PUD has become an integral part of modern manufacturing. With its low VOC content, excellent durability, and adaptability, industries strive for more eco-friendly and sustainable solutions.

The rise of PUD represents a shift toward more responsible and efficient industrial processes, offering a glimpse of the future where high performance and environmental stewardship go hand in hand. Whether you’re working in automotive coatings, textile manufacturing, or packaging solutions, it offers a strong, eco-friendly option that meets the demands of modern applications.

Also Read: The Impact of Automation and Digital Integration on the Flow Cytometry Market