In today’s business scenario, improving production processes and supply chain management has become crucial. Organizations that aim to stay competitive must develop methods for optimizing resource utilization, meeting customer demands, and minimizing operational costs. One such highly effective method for this aspect is the implementation of Advanced Planning and Scheduling (APS) systems.

APS tools marry production, inventory, and transportation planning to allow organizations to plan in real-time, thus giving perfect insights into operations activities, and with all this, businesses can make informed decisions in real-time. This blog explores the principles behind APS, its benefits, and its potential impact on industries.

What is Advanced Planning and Scheduling?

APS refers to tools and technologies designed to help organizations optimize and control their production and supply chains. Though traditional planning systems strictly rely upon the schedules plans, APS permits dynamic changes in plans at any time, considering the changes in demand failures in supplies or capacity constraints.

Using highly advanced algorithms and data analytics APS tools produce optimal production plans aligned with business objectives. Integration with procurements, manufacturing, and logistics is an essential feature of APS. This way, businesses can develop synchronized plans, improve efficiency, and reduce lead times.

The Need for Advanced Planning and Scheduling Systems

To understand better what is required from planning solutions in car manufacturing, let’s consider how complicated this process is. While the average car contains close to 1,800 large parts, when all small pieces like nuts and bolts are included, the figure amounts to around 30,000 parts. In 2022, Toyota produced approximately 8.1 million cars, about 1,000 every hour! To achieve this, they must ensure that all 30,000 parts are available and in the right place for every car. Such complexity requires more than simple planning techniques.

Since Toyota operates on a global scale, more advanced systems to manage production capacity and output are necessary. They require highly sophisticated scheduling tools that can handle large-scale work plans and timelines. Both of these needs can be addressed by an APS system. Now that we’ve discussed the importance of APS systems, let’s explore how they differ.

Benefits of Implementing Advanced Planning and Scheduling

Proactive Planning and Coordination improves the synchronization of manufacturing processes and provides greater visibility to increase utilization and on-time delivery while reducing inventory levels and waste.

| Benefits | Description |

| Enhanced Efficiency | APS allows for the optimal scheduling of resources. This schedule can accommodate more batches. The production company could, therefore, optimize the activities of its manufacturing area, prevent more instances of downtime and bottlenecks, and experience lower lead times while also keeping the operational expenses down, which contributed to bringing in the profit gain. |

| Resource Utilisation | Maximizing output also has the added benefit of reducing unnecessary waste, which saves costs and positions the manufacturing operation toward a more competitive and sustainable standpoint. |

| Reduced lead times | APS abbreviates production lead times and responds better as it improves coordination among stages of the production process. Shorter order fulfillment cycles also enhance a firm’s response to market demands. |

| Cost Savings | Companies will save huge amounts of cost in terms of efficient allocation of resources and production process flows. Other operational overheads over overtime labor and materials wastage are also reduced and, as such, result in better financial efficiency. |

| Accurate Forecasting | APS gives manufacturers the prescience of demand, which accordingly optimizes their levels of stock and reduces the possibility of under/over stocking. |

| Real-time Visibility | With real-time, accurate visibility of what is happening on your shop floor, you can keep tabs and adjust all these processes; it will also help managers and senior leaders make quicker, proactive decisions. |

| Customer Satisfaction | Shorter lead times and on-time deliveries feed directly into client satisfaction, helping to foster trusting relationships and a loyal customer base. |

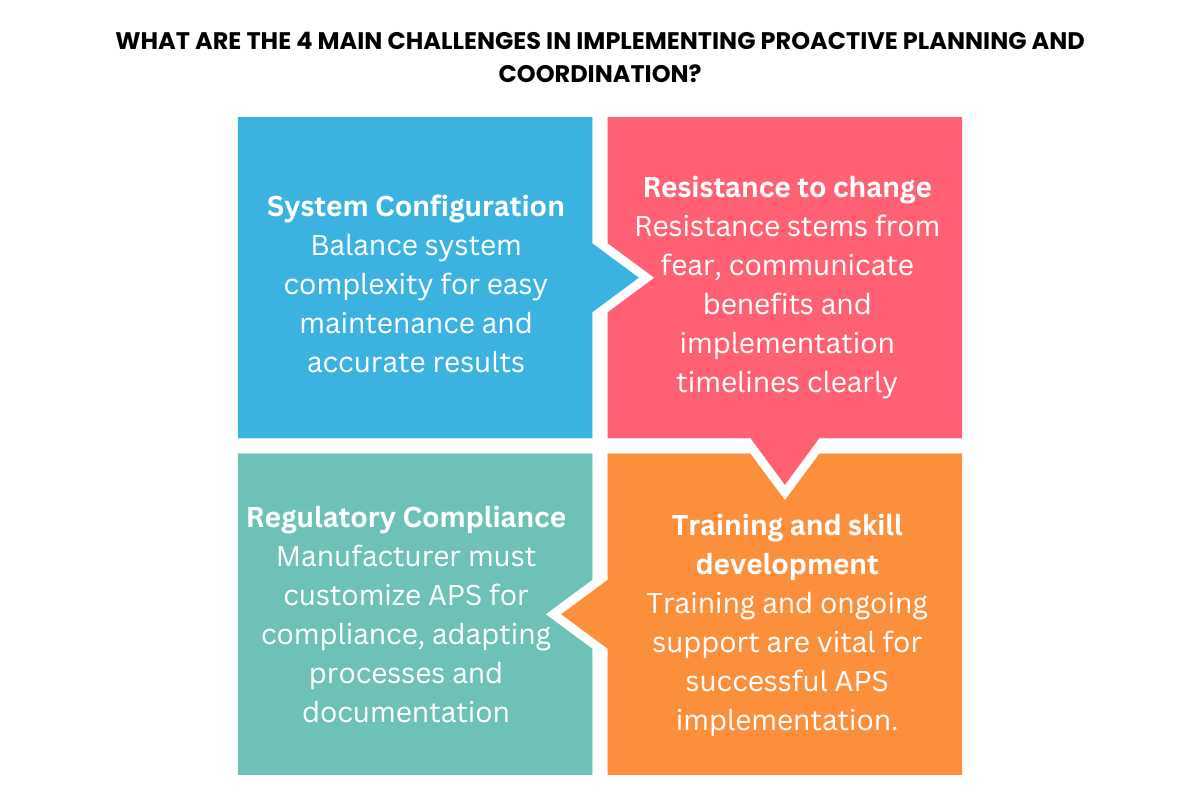

What are the 4 main challenges in implementing Proactive Planning and Coordination?

The APS tools help improve manufacturing production and management. Here are some key challenges manufacturers often face while implementing an effective APS system.

Future of APS

As industries evolve and develop, Advanced Planning and Scheduling will become increasingly crucial. Proactive Planning and Coordination help businesses plan their activities more effectively and ensure that the necessary resources are available when needed. With AI and ML integrated into APS systems, these tools will be more intelligent and capable of predicting changes in demand.

These will allow businesses to prepare well in case of shifts in demand. If the demand for a product surges, AI will provide early warnings to companies, enabling them to make appropriate decisions regarding production and supply.

The complication and global nature of supply chains-the event by which products may come from different countries and require movement through various locations- APS tools should then be able to handle such complexities in real-time, or this could become problematic. There will be a need for numerous quick changes due to a delay in shipment or overnight changes in consumer preferences. APS will help manage these effectively, ensuring a smooth operation while keeping customers satisfied.

Conclusion

In today’s highly competitive global market, businesses need an edge to outpace their competitors. Advanced Planning and Scheduling offers a powerful solution for optimizing production processes, reducing costs, and enhancing customer satisfaction. Companies that implement the APS system and utilize key sub-keywords such as supply chain optimization, capacity planning, and inventory management will streamline their operations and achieve sustainable growth. Thanks to advancements in technology, there are promising prospects in the field of APS, along with advanced tools available for businesses in the digital world.

Also Read: The Future of Mobile Dining: Top Trends Shaping the Food Trucks Industry