In the realm of advanced manufacturing and material processing, innovation often emerges from the convergence of diverse disciplines. Microwave-based plasma systems represent a prime example of such interdisciplinary synergy, offering a versatile and efficient approach to a wide range of industrial applications. From surface modification and thin film deposition to nanomaterial synthesis and waste treatment, these systems harness the power of plasma generated by microwaves to enable precision engineering at the atomic level. In this article, we delve into the fundamentals of microwave-based plasma systems, explore its diverse applications, and envision its transformative potential in shaping the future of materials science and manufacturing.

Understanding Microwave-Based Plasma Systems:

At the heart of microwave-based plasma systems lies the principle of plasma generation through the interaction of electromagnetic fields with gas molecules. Unlike traditional plasma sources, such as radiofrequency (RF) or direct current (DC) discharges, microwave-based plasma systems leverage the unique properties of microwaves to achieve higher plasma densities, lower operating pressures, and enhanced energy transfer efficiency. This enables precise control over plasma parameters, such as temperature, composition, and spatial distribution, facilitating tailored material processing with unparalleled precision and reproducibility.

The core components of a microwave-based plasma system typically include a microwave generator, waveguide, plasma chamber, and process control unit. The microwave generator produces high-power microwaves at frequencies ranging from gigahertz to terahertz, which are then coupled into the plasma chamber through a waveguide. Within the chamber, the microwaves interact with the process gas, ionizing it and initiating plasma discharge. Advanced control algorithms govern the system operation, regulating parameters such as microwave power, gas flow rate, and pressure to achieve desired processing outcomes.

Applications Across Industries:

Microwave-based plasma systems find widespread application across diverse industries, spanning materials science, semiconductor manufacturing, aerospace, energy, and environmental remediation. One of the primary applications is surface modification, wherein plasma treatment alters the chemical composition and morphology of material surfaces to enhance adhesion, wettability, and biocompatibility. This technique is extensively employed in the production of biomedical implants, electronic devices, and functional coatings.

Moreover, microwave-based plasma system-enhanced chemical vapor deposition (PECVD) enables the deposition of thin films with exceptional uniformity, purity, and adherence. This process is indispensable in semiconductor fabrication, where it is utilized for the deposition of silicon dioxide, silicon nitride, and other dielectric and conductive films in integrated circuit manufacturing. Additionally, microwave plasma systems facilitate the synthesis of nanomaterials, including nanoparticles, nanowires, and quantum dots, through controlled gas-phase reactions and nucleation processes.

In the aerospace and automotive industries, microwave-based plasma technology offers novel solutions for surface cleaning, coating removal, and thermal barrier coating deposition. Plasma cleaning effectively removes contaminants, oxides, and organic residues from metal, ceramic, and polymer surfaces, ensuring optimal adhesion and performance of subsequent coatings or adhesive bonds. Furthermore, the deposition of thermal barrier coatings using plasma spraying enhances the durability and heat resistance of engine components, contributing to improved fuel efficiency and engine lifespan.

Emerging Frontiers and Future Prospects:

As the pace of technological innovation accelerates, microwave-based plasma systems continue to push the boundaries of possibility in materials processing and nanotechnology. Advancements in plasma chemistry, reactor design, and process monitoring are enabling the development of novel materials with tailored properties and functionalities, revolutionizing fields such as optoelectronics, energy storage, and catalysis.

Furthermore, the integration of artificial intelligence and machine learning algorithms into plasma processing workflows holds the promise of autonomous optimization and adaptive control, enhancing process efficiency, yield, and reliability. Real-time diagnostics and in-situ characterization techniques, such as optical emission spectroscopy and mass spectrometry, provide valuable insights into plasma kinetics and reaction pathways, enabling precise process control and predictive modeling.

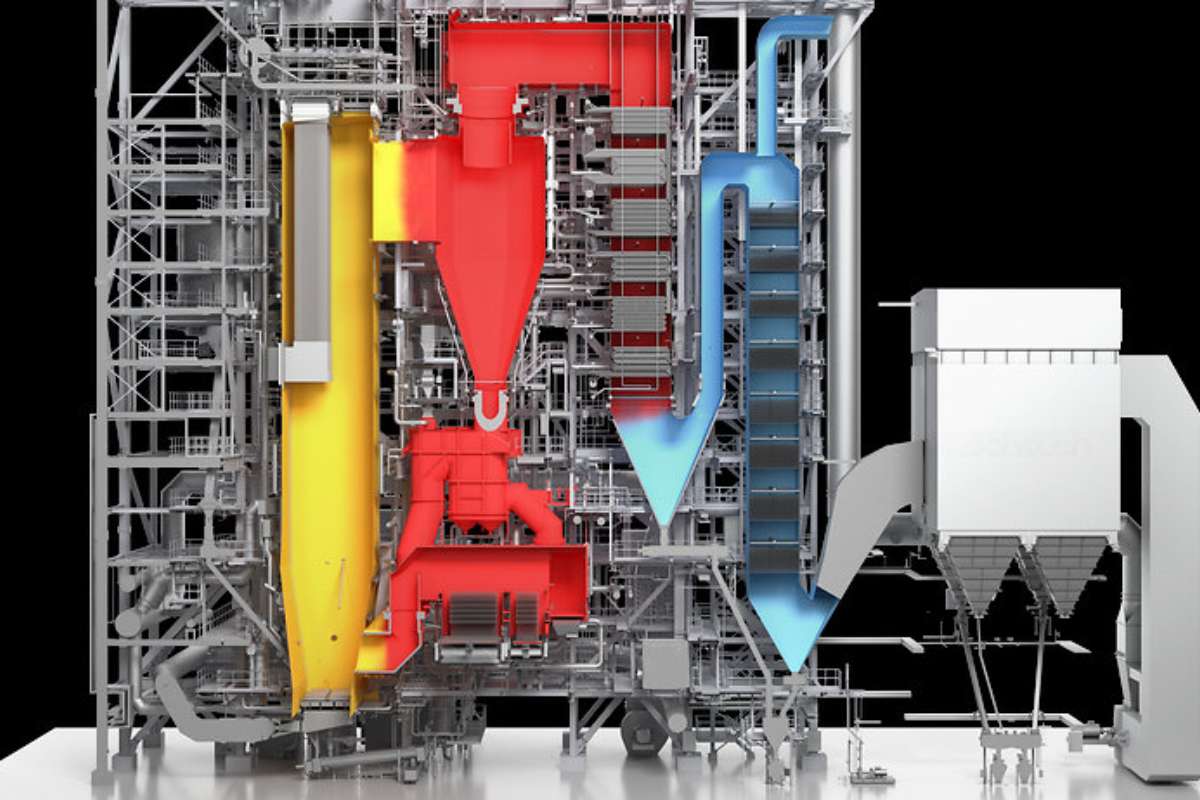

In the realm of environmental sustainability, microwave-based plasma systems offer innovative solutions for waste treatment, pollution remediation, and resource recovery. Plasma-assisted gasification and pyrolysis processes enable the conversion of organic waste into syngas or biochar, reducing landfill volumes and mitigating greenhouse gas emissions. Additionally, plasma catalysis holds the potential for the degradation of organic pollutants and the synthesis of value-added chemicals from waste streams, contributing to the circular economy and resource conservation.

Conclusion:

Microwave-based plasma systems represent a paradigm shift in materials processing, offering unparalleled versatility, precision, and efficiency across a spectrum of industrial applications. From surface modification and thin film deposition to nanomaterial synthesis and environmental remediation, these systems embody the convergence of advanced plasma physics, materials science, and engineering innovation. As research and development efforts continue to expand the frontiers of plasma technology, the transformative impact of microwave-based plasma systems on manufacturing, energy, and sustainability promises to shape the future of industry and society.